Industrial inspection and automation

Automation, robotization, industry 4.0, integration of quality control in ongoing production or at the end of the production line lead to increasingly faster cycle and throughput times with a growing number of product variants.

Zero-error tolerance, digital networking, AI and deep learning systems - these are some of the developments that are increasingly determining the industrial working environment and that require the solid support of industrial cameras.

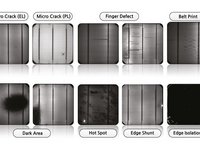

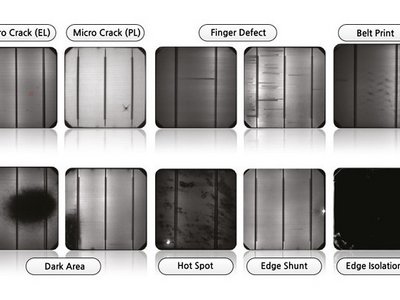

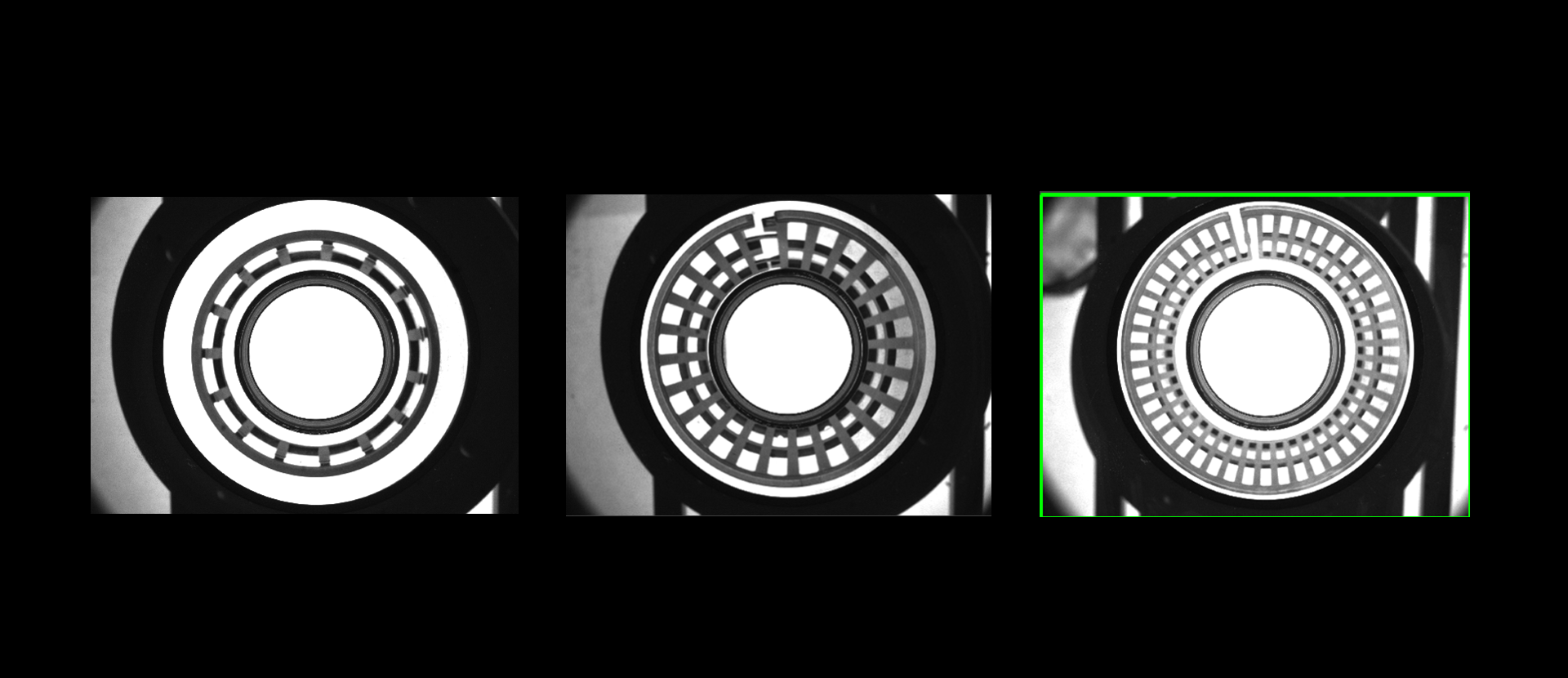

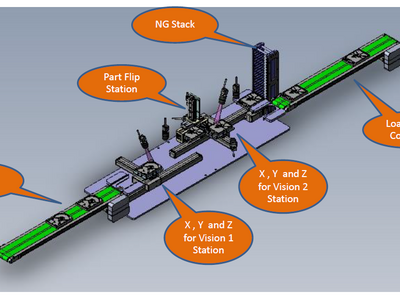

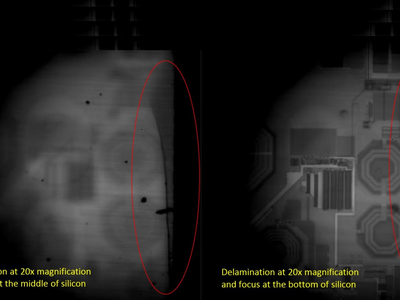

In all industry sectors, vision systems are indispensable in automated processes for meeting today's requirements in terms of production speed and quality. The specific tasks of camera-based systems can be very different: from pick and place and sorting, defect detection and non-conformity check to metrology and measurement.

The goal is to further automate manufacturing up to so called "Lights-out-factories". To further reduce need for human interaction in manufacturing, powerful and highly reliable vision systems are crucial.

Typical applications

Finding the right camera for your application

For more than 30 years, Allied Vision has been helping people to reach their imaging goals. By focusing on what counts for each customer, Allied Vision finds solutions for every application, a practice which has made Allied Vision one of the leading camera manufacturers worldwide in the machine vision market.

Our engineers design digital cameras with a large scope of resolutions, frame rates, bandwidths, interfaces, spectral sensitivities, sensor technologies, and technical platforms.