When speaking about camera technology cleanliness is defined by the vision application – or to put it even simpler: cleanliness is defined by the customer of a camera manufacturer.

Based on the optical parameters unwanted particles are most critical for microscopy applications. “The closer you look the more you can see” – it is obvious, that especially in microscopy applications like cell counting, PCR testing, urin analysis or pathology already very small unwanted particles in the optical path can have a negative effect on the analysis of the images.

In general, vision applications with large magnifications and small apertures (large f/ numbers) need high cleanliness requirements. The following paragraphs show where and how to ensure cleanliness.

How to engineer Cleanliness?

Imaging Sensor

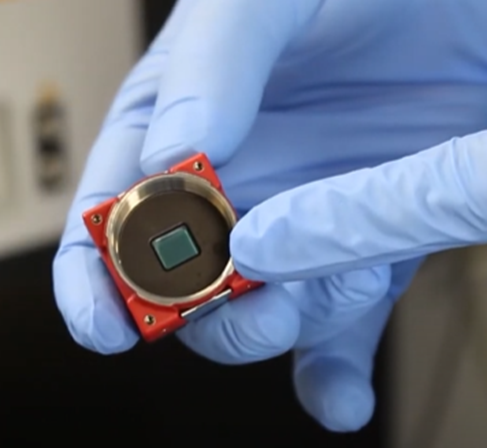

The imaging sensor is the heart of the camera and it´s the first point in the optical path where blemishes can cause unwanted effects in the later images. A sensor (pack) can show potential unwanted effects either caused by particles between sensor glass and sensor pixels or by inclusions in the sensor glass itself.

Most camera manufacturers buy their imaging sensors from sensor suppliers like Sony, Samsung or Omnivision. Of course, sensor suppliers define their quality levels as well. Those quality levels have direct impact on yield/scrap rate in the semicon industries. Sensor production follows the strict rules of mass production – when a sensor supplier specifies a certain sensor and its quality level, he aims at a certain target application (e.g., automotive, defense, science). Production volumes, target costs/price and quality level for a certain sensor are set based on the target application. Once defined by the sensor supplier the quality level is not negotiable.

In case a camera manufacturer wants to have a higher quality for his customer than delivered by the sensor supplier, the only answer is testing and sorting of sensors at the IQC (incoming quality control).

Manufacturing

Our Alvium Camera production line works under clean room conditions and shows an impressive level of cleanliness. The production process is highly automated; tolerance values and test results for each single Alvium Camera are documented in our production data warehouse.

For customers with advanced cleanliness requirements the EoL (end of line) test can be adapted to a higher f/ number. Final images and data can be made available.

After EoL test the Alvium Cameras get a protective foil on top of the mount to make sure that during packaging and shipment no external particles come on the sensor glass.

Handling at Customer site

When the ordered batch of Alvium Cameras enters the warehouse or production of the customer it is important to follow some rules:

- When doing IQC cameras should always be carried mount down to avoid particles falling on the sensor area.

- When the protective foil has been removed the cameras should be handled in a controlled atmosphere only – ideally clean room environment.

- In case the cameras get contaminated there should be trained staff and tools to clean the camera if needed.

Design of the OEM product

Depending on the mechanical design there can be another potential risk to bring in unwanted particles into the optical path. When screwing in an optic into the camera mount particles can potentially be generated by friction in the threads (see picture).

We recommend checking tolerance fields of both threads (mount and optic) and the material mix for hardness.

Such risk of particles can also be avoided by a design change – one alternative design could be to glue in the optic.

The camera delivered by a supplier is the central component when looking at cleanliness, but also manufacturing, handling and product design by the OEM are important fields to reach the required cleanliness level. From our experience it is very fruitful to discuss cleanliness requirements between Supplier and OEM right from the start.