Applications

Energy & Environment

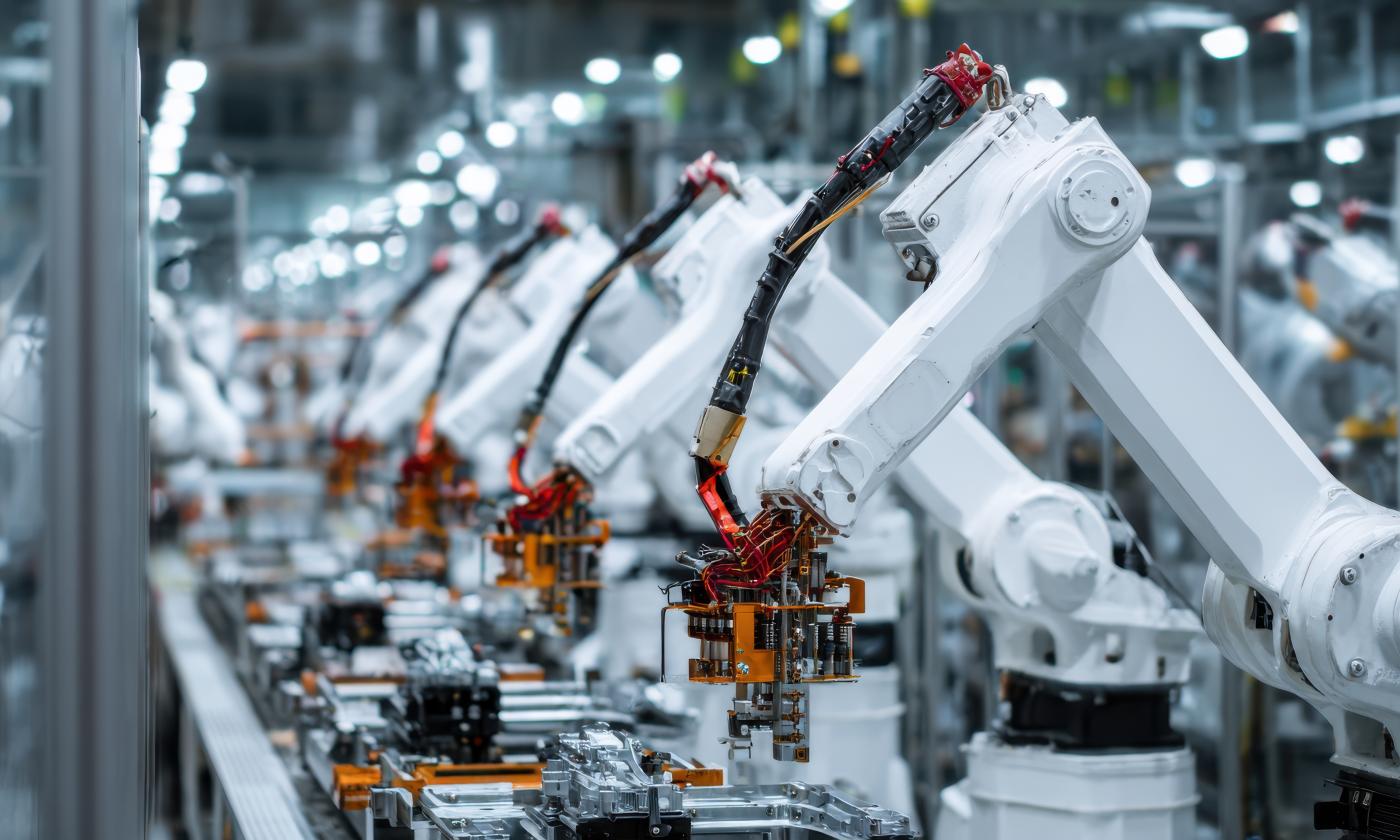

Rechargeable Battery Production

Battery Technology Inspection Cameras For Precision Manufacturing And Defect Detection

Monitor Every Layer Of Rechargeable Batteries With Unmatched Resolution

Ensure precise inspection and alignment of battery cells with industrial cameras. Optimize e-mobility production, improve quality, and reduce defects in rechargeable battery manufacturing.

Technical Requirements

- High resolution cameras enabling the inspection of battery cells with fine structures and thin layers

- Low-noise camera providing clear images to monitor intermediate products and batteries

- High frame rate for fast, uninterrupted battery production lines

- Line scan cameras for foil testing in battery cells

Do You Have Any Questions? We Are Here To Help.