Applications

Electronics, FPD & Semiconductors

Semiconductor Inspection

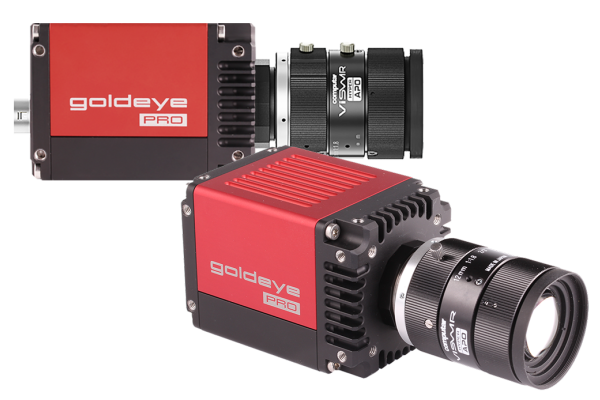

Semiconductor Inspection Cameras For Advanced Wafer Surface Analysis

Detect Defects Precisely For Consistent, High-Quality Semiconductor Output

Achieve superior semiconductor quality with industrial cameras designed for precise inspection. Enhance defect detection and process reliability in production.

Technical Requirements

- High spatial resolution imaging for reliable defect detection in wafer or semiconductor production

- SWIR sentitive cameras seeing through all layers with the highest levels of accuracy

- High bandwidth for semiconductor inspection requiring high-definition imaging

- State-of-the art sensors running at high frame rates for increasing production throughput

Do you have any questions? We are here to help.